Products

Information

Information

Home> Products Information > V600 SERIES

Product Overview

Introduction our recent innovations

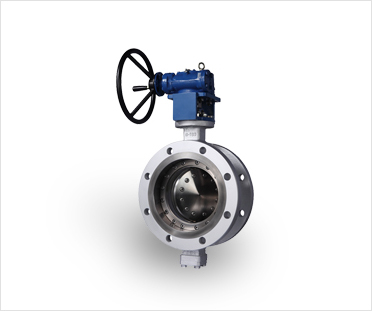

- Standard Body Specification : Triple Offset Butterfly Style

-

standard specification Size 3” to 44” (DN80--1100) Rating ANSI 150LBS to 1500LBS Leakage ANSI FCI 70-2

Standard : Class(Metal Seat)Ⅴ

Option : Class ⅥCv Range 130 to 80,000 Press. Range Up to 3,700 psi (g)

Up to 260 Kg/cm²Temp. Range -150℉ to +1,050℉

-100℃ to +565℃

Option : -320℉ to +1,562℉

-196℃ to +850℃Materials Carbon steel(WCB,WCC),

Stainless steel(CF8,CF8M,CF3,CF3M)

Chrome-moly(WC6,WC9,C12A)

other alloysEnd Connections Wafer Flange less,

Lugged, Double FlangeActuators Spring-diaphragm, Cylinder, Motor,

Electro-HydraulicApplications Oil and Gas Storage, Transportation, Gathering Systems

LPG and LNG Production, Storage, Transportation

Petrochemical Industry

Refining Industry

Power Generation

Pulp and Paper Industry

- Feature

-

No - Friction

The triple offset eliminates all friction throughout the operating cycle.

And a vastly extended valve life. -

No - Over travel

The triple offset is the geometry design of the angle cone disc sealing components.

Contact is only made at the final point of closure with the 90 degrees

acting as a mechanical stop : resulting in over travel of the disc set. -

Wide range

Non-galling design enable a wide variety of meterials options and wide

range of applcations from the low to high temperature & pressure. -

Zero - Leakage

Metal to metal sealing allowing for higher pressure and temperature applications

whilst still providing tight shut off. -

Ease - Maintenance

Field replaceable seat and seal ring reduces maintenance costs.

- Geometry

-

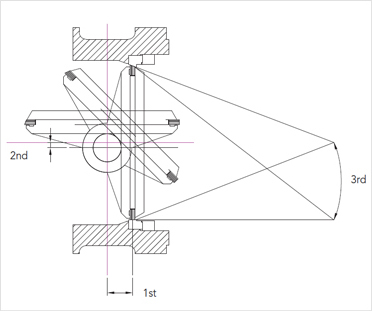

Single Offset - 1st offset

To allow displacement of the seat the shaft is offset from the center line of

the seat and body seal. -

Double Offset - 2nd offset

The center line of the bore.

This creates a cam action during operation to lift the seat out of the seal resulting in

friction during the first 10 degrees of opening and final 10 degrees of closing. -

Triple Offset - 3rd offset

The third offset is the geometry design of the sealing components

not the shaft position.

The sealing components are each machined into an offset conical profile

resulting in a right angled cone(see Fig 1-3rd).

Our Company

Our Company